|

Product Details:

|

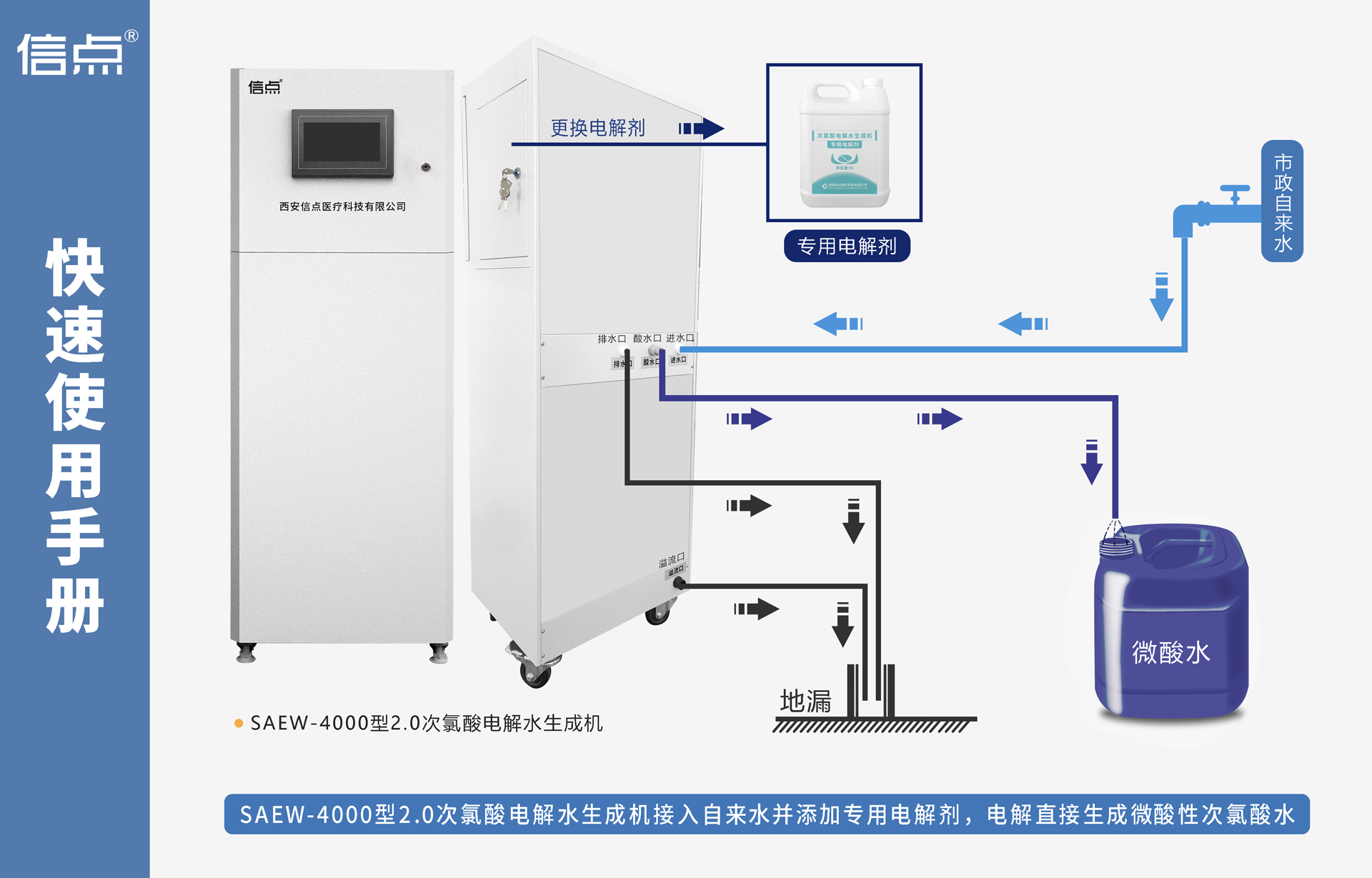

Hypochlorous Acid Production System is composed of water system, diaphragmless electrolytic tank and control device.

The shell of the machine is made of high-quality anti-corrosion, rust-proof and firm materials.

The electrical control system inside the machine is connected to the operation panel and display. There is a cooling fan inside the machine and the side panels are equipped with ventilation openings. The inside water system is consists of water filtration device and control device.

In order to ensure the quality of hypochlorous acid solution and maintaining the quality of electrolytic tank, the feed water should meet the requirements of the machine. The feed water pressure should be 0.2-0.4Mp a, tatal dissolved solids (TDS) should be less than 300ppm.

EV HOCl-100

Table 1 Technical parameters of EV-HOCl-100 Hypochlorous Acid Production System.

| Items | Technical parameters |

| System control unit | High-performance embedded industrial microprocessor |

| System resources | Integrated functions, muti-channel program control |

| Operation interface | One-touch operated display panel |

| Software information | Release Version V1 |

| Sterilized water output | ≥100L/h (depending on the water quality, the amount varies) |

| Electrolyte tank | 35L |

| Additive tank | 5L |

| Properties of the generated hypochlorous acid solution | pH: 5.0-7.0 |

| ORP≥900mV | |

| Free Chlorine: 450 mg/L -500 mg/L | |

| Input vector | AC220V±10% 50Hz |

| Maximum power consumption | 750VA |

| Contiguity | Continuous electrolysis |

| Size | 470mm*380mm*1360mm |

| Requirements for installation and use conditions | Temperature 5-40ºC |

| Humidity: ≤80% | |

| No strong electromagnetic interference around | |

| Line with voltage-stabilized source | |

| Reliable grounding power | |

| Feed water | Tap water, Pressure: 0.2-0.4Mpa, TDS≤300ppm. |

| Pipe | 3/8 Food grade PE pipe |

Contact Person:Leigh Ma